The outbreak of the new energy market

The new energy market has exceeded 100 billion yuan and has become the core driving force for the development of the industry. The rise of new energy has not only brought about profound changes in the industry structure, but also promoted the explosive growth of the market size. At present, the new energy market has exceeded 100 billion yuan and has become the core force driving the development of the industry. It is expected that by 2025, the market size will exceed 120 billion yuan, of which the market size of wiring harnesses for new energy vehicles will reach 75 billion yuan.

The share of new energy vehicle wiring harnesses in the market surged from 4.8% in 2019 to 62.5% in 2025, mainly due to the addition of high-voltage wiring harness systems. In 2023, the market size of China's automotive wiring harness market has reached an astonishing 107.03 billion yuan, a significant increase of 31.39% year-on-year. Looking ahead, by 2025, this figure is expected to exceed 120 billion yuan. It is worth noting that the proportion of new energy vehicle wiring harnesses has surged from 4.8% in 2019 to 62.5% in 2025, and the market size is as high as about 75 billion yuan, becoming the main driving force for market growth. This significant change is mainly due to the new high-voltage wiring harness system of new energy vehicles, such as fast charging wiring harnesses and battery pack wiring harnesses, which have increased the value of bicycles to more than 5,000 yuan, an increase of more than 60% compared with 3,000 yuan for fuel vehicles.

Technological innovation of high-voltage wiring harnesses

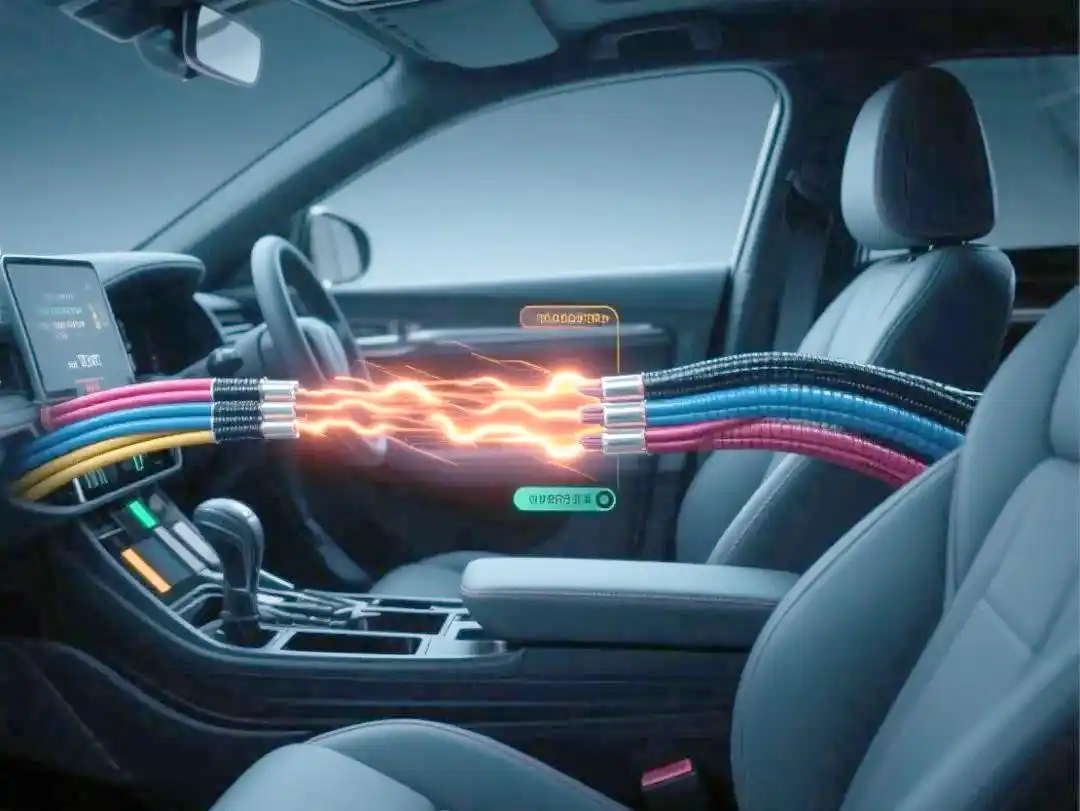

△ High-voltage wiring harnesses increase the value of bicycles

The wide application of high-voltage wiring harness systems has increased the value of bicycles from 3,000 yuan to more than 5,000 yuan, promoting the rapid growth of the automotive wiring harness market. With the vigorous development of the new energy vehicle market, high-voltage wiring harness systems such as fast charging wiring harnesses and battery pack wiring harnesses have become the key to technological upgrading. These high-voltage wiring harnesses not only increase the value of bicycles, but also promote the rapid growth of the entire automotive wiring harness market.

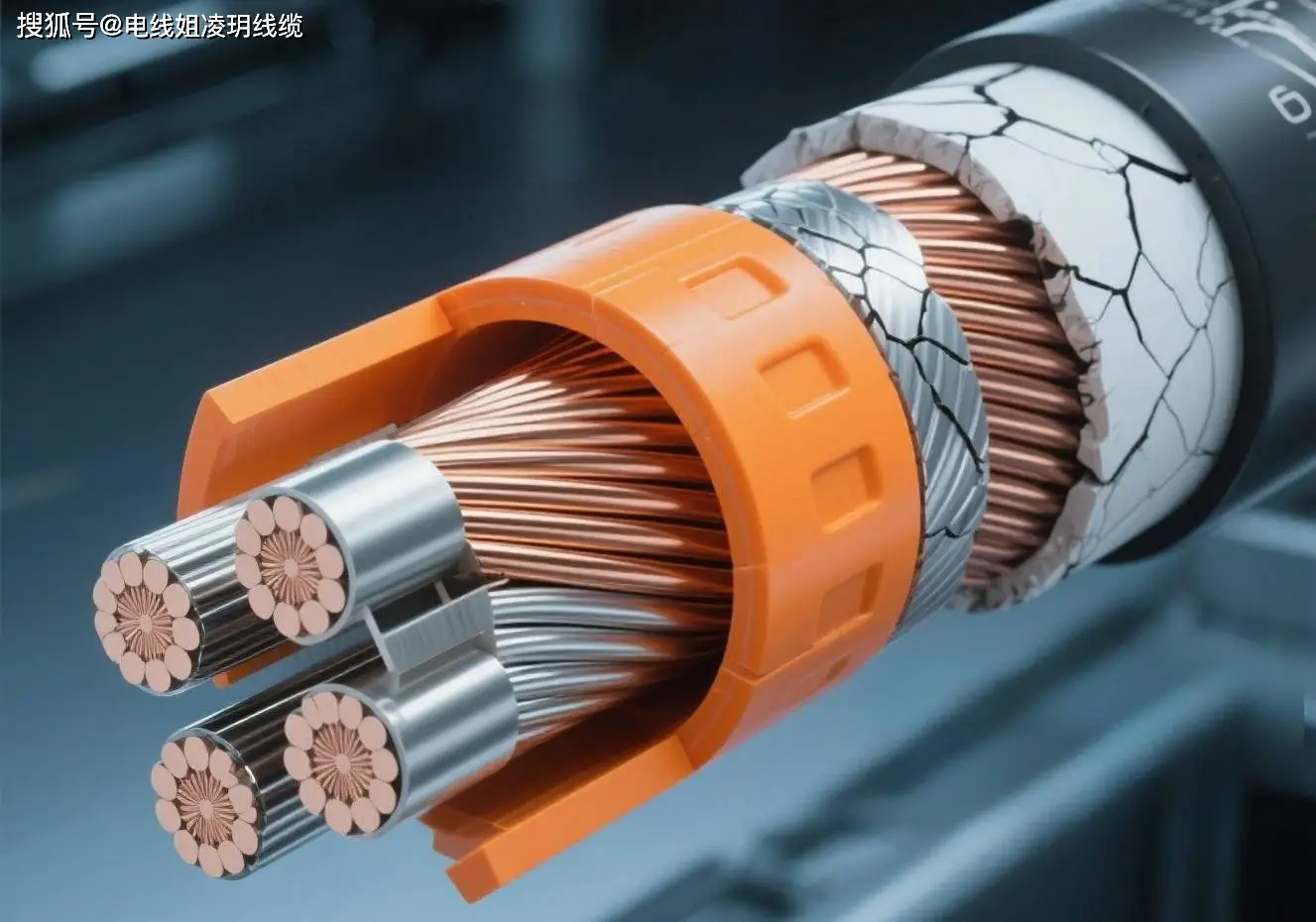

△ Technological breakthroughs and lightweight development

Silicone insulation and innovative shielding structures have become the focus of technological breakthroughs, and liquid cooling design has played a significant role in improving it. The widespread adoption of 800V platforms has greatly promoted the leap in performance of high-voltage wiring harnesses. The withstand voltage level has been increased from the original 600V to more than 1500V, indicating that the high-voltage wiring harness technology has entered a new stage of development. The industry has faced many challenges. Silicone insulation, innovative three-layer electromagnetic shielding structure (combined with copper braid, aluminum foil and absorbing layer), and liquid-cooled heat dissipation design have become key technological breakthroughs. For example, CATL and Aptiv have jointly developed 1000V liquid-cooled wiring harnesses, fully demonstrating the role of these technologies in promoting the performance improvement of high-voltage wiring harnesses.

Lightweight and intelligence are the key directions of future development. In terms of high-voltage and high-frequency transmission technology, high-voltage wiring harnesses need to support current transmission of more than 400A, the cross-sectional area of the wire is increased from 35mm² to 70mm², and the connector plating has also shifted from gold plating to silver-nickel alloy to further reduce resistance. In terms of signal transmission, with the popularization of L3+ autonomous driving technology, automotive Ethernet wiring harnesses (with 10Gbps bandwidth) are gradually replacing traditional CAN buses. The ideal L9 model adopts Ethernet as the backbone design, which reduces the length of the wiring harness by 40% and the delay by 60%, fully demonstrating the great potential of new technologies in improving automotive performance.

Lightweight materials and intelligent manufacturing

△ Application and transformation of aluminum wires

Aluminum wires replace copper in high-voltage wiring harnesses, with a conductivity of 97% of copper, while reducing weight by 30% and cost by 40%, which not only helps to promote the lightweight development of high-voltage wiring harnesses, but also helps to improve the overall performance of automobiles and reduce energy consumption. The adoption of aluminum instead of copper, an innovative initiative that has made significant strides in the field of high-voltage wire harnesses. Aluminum wires have a conductivity of up to 97% of copper, while reducing their weight by 30% and significantly reducing costs by 40%.

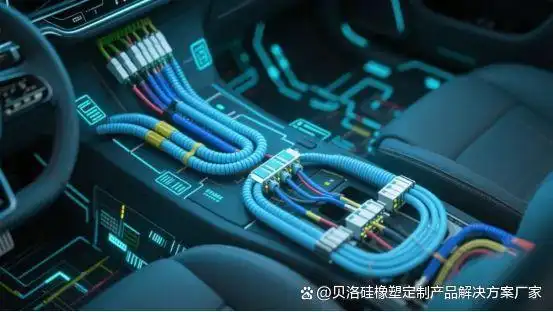

△ Structural optimization and intelligent manufacturing

The use of carbon fiber composite materials and thin-wall technology to reduce the weight of wiring harnesses, AI quality inspection to improve manufacturing efficiency, and it is expected that by 2025, the automation rate of domestic factories will reach 75%. By using carbon fiber composite sheath and thin-wall insulation technology (wall thickness of only 0.1 mm), the weight of the wiring harness is significantly reduced, up to 60%. This structural optimization measure not only improves the endurance of the vehicle by 5%-10%, but also brings significant efficiency improvements to the automobile manufacturing field. In addition, the introduction of intelligent manufacturing is also a highlight. With the help of AI quality inspection and machine vision technology, the defect rate has been greatly reduced, from the original 0.5% to 0.1%, bringing significant efficiency improvement to the factory, and it is expected that by 2025, the automation rate of domestic factories will reach 75%, and labor costs will be reduced by 40%.

The accelerated breakthrough of local enterprises

△ Market share increased

The market share of local Chinese companies has risen from 3% to 28%, and local suppliers have become the first choice for new car companies, accelerating the process of domestic substitution. Against the backdrop of 71% of CR3 in the global market, the market share of local Chinese enterprises has climbed from 3% to 28%, showing strong market competitiveness. Domestic car companies are 40% lower in cost than foreign capital, and the response cycle is also shortened by 30%, which brings huge advantages to local suppliers. New power car companies such as NIO and Ideal are more inclined to choose local suppliers to shorten the customized development cycle from 12 months to 8 months, further accelerating the process of domestic substitution.

△ Regionalized capacity layout and favorable policies

Local enterprises have enhanced their delivery capabilities through regional capacity layout, and policy dividends and carbon credit policies have promoted the development of the wiring harness industry towards lightweight. Regional production capacity layout is also an important strategy for local enterprises. For example, the production capacity of the Yangtze River Delta cluster covers 50% of the market demand, and Henan Tianhai Group occupies 20% of the domestic market share, which ensures the delivery resilience of enterprises. At the same time, the two-way empowerment of policy and ecology has also brought new development opportunities to local enterprises. Policy dividends continue to be released, promoting the localization of key components, and the carbon credit policy is encouraging the development of wiring harnesses to lightweight. In addition, the EU's new battery regulation requires harness recycling to be high, forcing the application of bio-based materials, such as BASF's Ultramid® Bio, to reduce carbon emissions by 60%.

05Global layout and technology output

△ Regionalization of production capacity and technology authorization

Through global layout and patent and technology licensing, Chinese enterprises have enhanced their competitiveness in the global market, and the competition for technological commanding heights has intensified. Looking forward to the future, the competition for the commanding heights of globalization and technology will become a new trend in the industry. Technology integration is accelerating, and high-voltage-supercharging ecology and wireless-wired hybrid architecture will become new hotspots in the industry. 4C fast charging technology achieves a range of 400 kilometers in 10 minutes, and liquid-cooled wiring harnesses have become standard; The UWB technology used by the BMW iX reduces the number of door harnesses by 12, indicating that hybrid architecture will become the mainstream in the future. These trends will bring new challenges and opportunities to local enterprises, driving the entire industry to a higher level.

Regional layout of production capacity: For example, the establishment of the Mexican base is designed to serve the North American market and enjoy a 15% reduction in tariffs; Eastern European factories are responding to the EU's carbon tariff policy with up to 85% automation. Technology licensing innovation: CATL's CTP technology has been successfully licensed to Ford Motor Company, which not only helps Chinese companies open up new ways to go overseas under the restrictions of the US IRA Act, but also demonstrates new possibilities for technology licensing models.

![[list:title ] Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for](/runtime/image/mw200_mh_1754970367606571.png) Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for

Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for![[list:title ] 3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo](/runtime/image/mw200_mh_1754970445122718.png) 3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo

3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo![[list:title ] Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis](/runtime/image/mw200_mh_1754970599124240.png) Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis

Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis![[list:title ] Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M](/runtime/image/mw200_mh_1754970685778571.jpg) Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M

Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M![[list:title ] RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible](/runtime/image/mw200_mh_1754970772864871.jpg) RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible

RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible![[list:title ] Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P](/runtime/image/mw200_mh_1754970914446714.jpg) Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P

Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P![[list:title ] Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon](/runtime/image/mw200_mh_1754971132172086.jpg) Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon

Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon![[list:title ] 1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi](/runtime/image/mw200_mh_1754971206813424.jpg) 1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi

1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi![[list:title ] USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers](/runtime/image/mw200_mh_1751290248528158.png) USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers

USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers![[list:title ] Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine](/runtime/image/mw200_mh_1751290043732325.png) Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine

Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine![[list:title ] Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl](/runtime/image/mw200_mh_1751289911932558.png) Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl

Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl![[list:title ] OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir](/runtime/image/mw200_mh_1751289859503493.png) OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir

OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir![[list:title ] Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic](/runtime/image/mw200_mh_1751289819362910.png) Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic

Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic![[list:title ] Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C](/runtime/image/mw200_mh_1751289746509799.png) Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C

Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C![[list:title ] High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery](/runtime/image/mw200_mh_1751289703107392.png) High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery

High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery![[list:title ] High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC](/runtime/image/mw200_mh_1751289653205137.png) High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC

High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC![[list:title ] XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec](/runtime/image/mw200_mh_1751293406317163.png) XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec

XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec![[list:title ] XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3](/runtime/image/mw200_mh_1751293362444100.png) XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3

XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3![[list:title ] XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni](/runtime/image/mw200_mh_1751293307595602.png) XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni

XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni![[list:title ] Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou](/runtime/image/mw200_mh_1751293254961173.png) Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou

Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou![[list:title ] UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2](/runtime/image/mw200_mh_1751293224859016.png) UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2

UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2![[list:title ] PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St](/runtime/image/mw200_mh_1751293191631742.png) PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St

PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St![[list:title ] PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use](/runtime/image/mw200_mh_1751293135247963.png) PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use

PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use![[list:title ] OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co](/runtime/image/mw200_mh_1751293103170614.png) OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co

OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co![[list:title ] Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H](/runtime/image/mw200_mh_1751287652901338.png) Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H

Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H![[list:title ] Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation](/runtime/image/mw200_mh_1751287559833642.png) Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation

Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation![[list:title ] New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An](/runtime/image/mw200_mh_1751287256545420.png) New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An

New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An![[list:title ] M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw](/runtime/image/mw200_mh_1751287205474322.png) M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw

M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw![[list:title ] M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG](/runtime/image/mw200_mh_1751287108943181.png) M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG

M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG![[list:title ] JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes](/runtime/image/mw200_mh_1751287072360672.png) JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes

JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes![[list:title ] HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors](/runtime/image/mw200_mh_1751287006387917.png) HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors

HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors![[list:title ] High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe](/runtime/image/mw200_mh_1751286944271896.png) High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe

High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe