Automation: Free up manpower and improve efficiency and precision

Traditional wire harness production is highly dependent on manual labor, especially in back-end processes such as wiring, strapping, and assembly, which is not only inefficient, but also difficult to ensure product consistency. With the fading of the demographic dividend, labor costs continue to rise, and the difficulty of recruiting workers has become a common problem in the industry. Automated production has become the key to breaking the wire harness industry. At present, the wire harness front-end processes such as wire cutting, stripping, crimping, etc. have achieved a high degree of automation. Some advanced automatic wire cutting machines can accurately cut wires to a specified length according to preset programs, and the error can be controlled within a very small range, and their efficiency is several times or even dozens of times that of manual operation. In the terminal crimping process, automated equipment ensures that each terminal is crimped firmly and consistently by precisely controlling pressure and stroke, greatly improving product quality.

The back-end process is difficult to automate due to the variety of products and large process differences, but significant breakthroughs have also been made in the industry. The automated wiring equipment developed by some enterprises, using robotic arms and visual recognition systems, can quickly and accurately route the wire harness according to the design requirements, avoiding errors and omissions in manual wiring. The automatic strapping machine can automatically adjust the strapping force and position according to the size and shape of the wire harness to achieve efficient and neat strapping. According to industry data, after the introduction of automated production lines, the production efficiency of wire harnesses can be increased by 30%-50%, the product defect rate can be reduced by more than 50%, and labor costs can be saved by 40%-60%. Automated production not only improves production efficiency and product quality, but also allows enterprises to better cope with large-scale orders and enhance market competitiveness.

Digitalization: Data-driven, achieving precise management and flexible production

The wave of digitalization is sweeping the wiring harness industry, bringing a new model to production management. Through the networked monitoring of production equipment (MES system), cloud management of process parameters, and full traceability of quality data, digital factories have significantly improved production efficiency and quality stability. In the digital production environment, each equipment becomes a data collection point, uploading production data in real time, such as equipment operating status, output, defective product rate, etc. Managers can grasp the overall picture of the production site anytime and anywhere through computers or mobile phone terminals, and find problems and make adjustments in time.

For example, when a device has a fault warning, the system will automatically push information to the maintenance personnel and provide historical operation data and fault diagnosis suggestions for the equipment to help the maintenance personnel quickly locate and solve the problem. The full traceability of quality data is a major advantage of digitalization. The quality data of each wiring harness is recorded throughout the process from raw material procurement, production and processing to finished product delivery. Once a quality problem occurs, it can be quickly traced back to the source of the problem, whether it is a raw material problem, equipment failure or human operation error, so as to take targeted measures to avoid similar problems from happening again. Digitalization also opens up possibilities for flexible production. Through the analysis of market demand data, enterprises can quickly adjust production plans and achieve customized production of multiple varieties and small batches to meet the diverse needs of customers.

Integration: Collaborative innovation to create an efficient industrial chain ecology

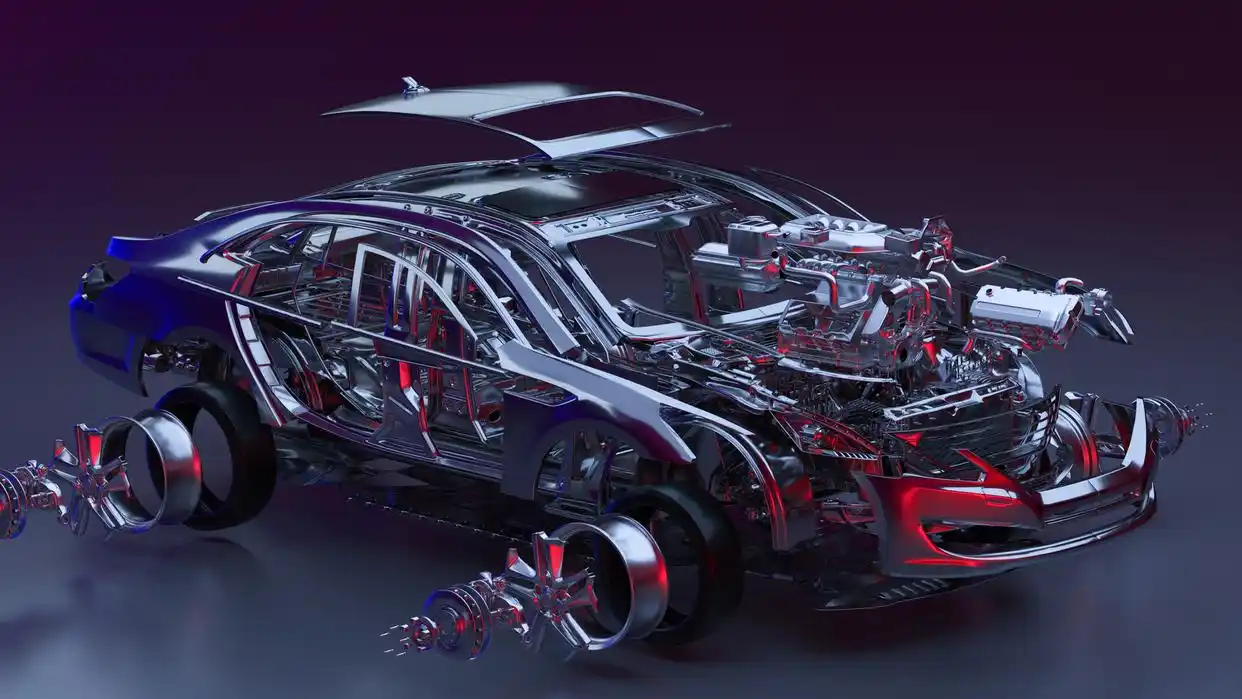

Integration is reflected in many levels. From the internal point of view of the enterprise, it is the integration and coordination of R&D, production, sales and other links. In the traditional model, these links are often relatively independent and the information flow is not smooth, resulting in long product development cycles and disconnection between production and market demand. Nowadays, with the help of digital technology, enterprises have established a unified information platform, and the R&D department can transmit the design data to the production department in real time after designing new products according to market feedback, and the production department can quickly formulate production plans according to the actual production capacity and inventory situation, and feedback the production progress to the sales department, and the sales department reasonably arranges sales strategies according to the production progress and market demand. This internal integration and collaboration greatly shortens the product launch cycle and improves the response speed of enterprises to the market.

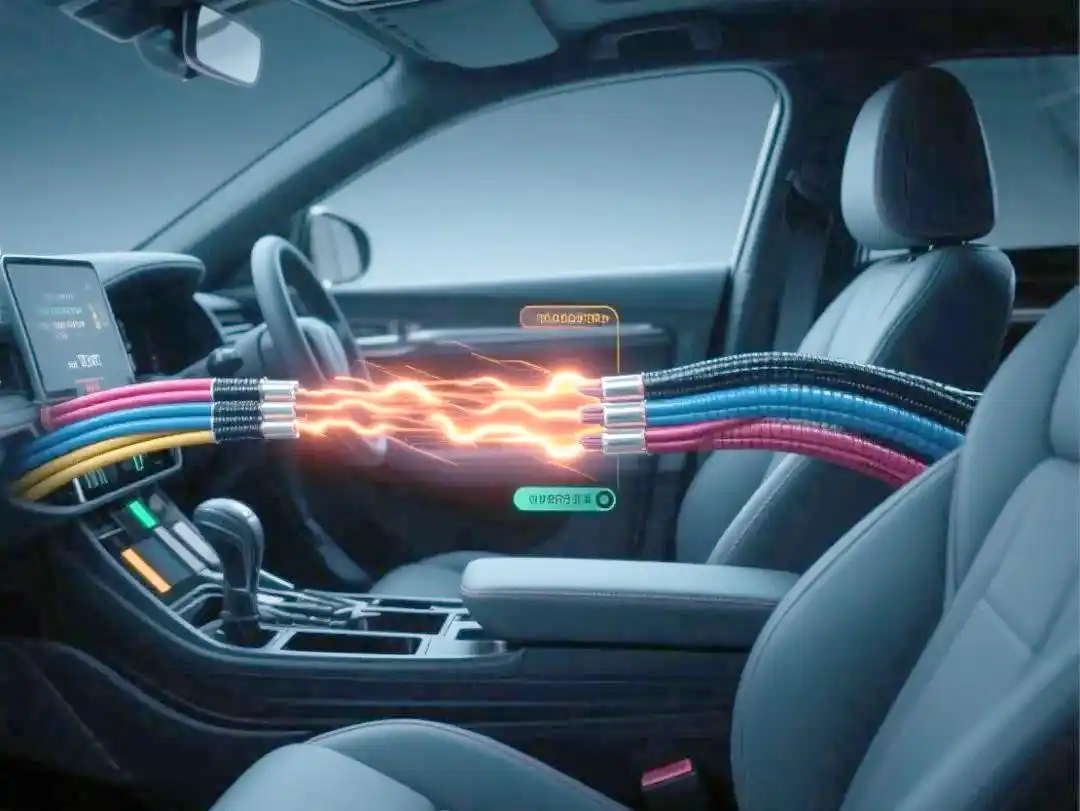

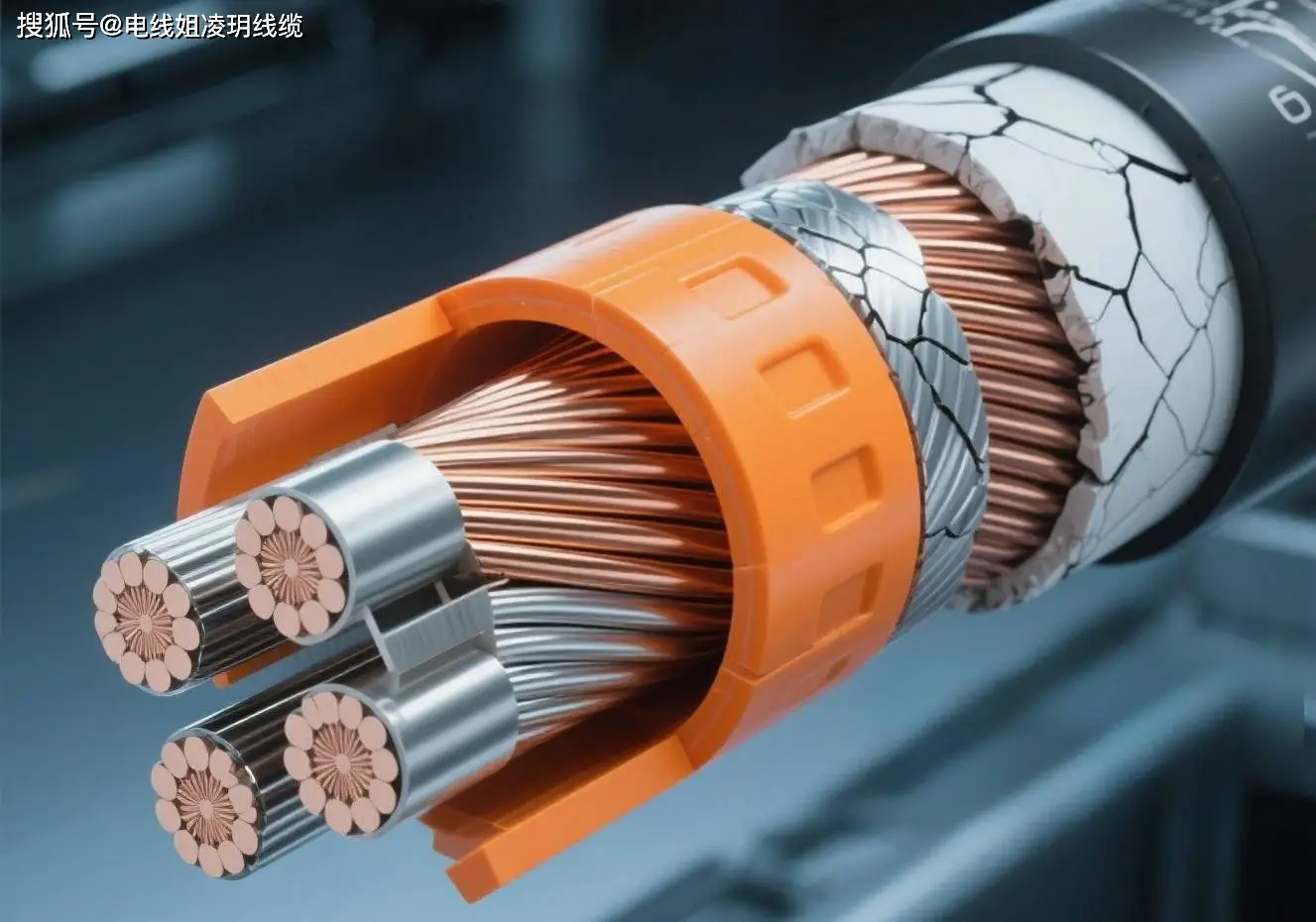

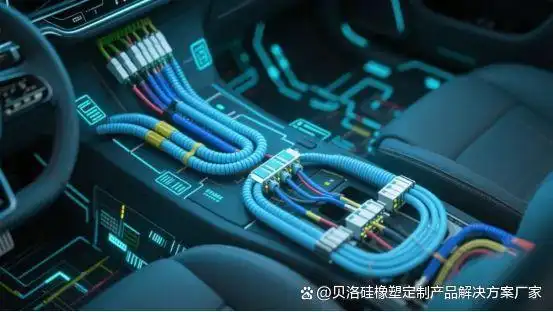

From the perspective of the industrial chain, integration is the deep integration between upstream and downstream enterprises such as OEMs, wiring harness suppliers, and parts suppliers. OEMs are sharing more R&D work with wiring harness suppliers to develop wiring harness systems for new models. Wire harness suppliers work closely with component suppliers to ensure the quality and supply stability of raw materials and components. Through the establishment of industrial alliances and collaborative innovation projects, upstream and downstream enterprises form an organic whole, realize resource sharing, complementary advantages, and jointly enhance the competitiveness of the industrial chain. For example, in the field of new energy vehicles, OEMs and wiring harness suppliers jointly develop high-voltage wiring harnesses and high-speed data transmission wiring harnesses to meet the needs of new energy vehicles for high voltage, high-current transmission and high-speed data processing, and component suppliers provide high-performance insulation materials, connectors, etc. to ensure the reliability of wiring harness systems.

The integrated development of automation, digitalization and integration will bring a qualitative leap to the wire harness production line. In this process, enterprises need to increase investment in technology research and development, cultivate and introduce professional talents, and actively cooperate with upstream and downstream enterprises in order to seize the opportunity in the fierce market competition and promote the wiring harness industry to a new stage of development.

![[list:title ] Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for](/runtime/image/mw200_mh_1754970367606571.png) Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for

Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for![[list:title ] 3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo](/runtime/image/mw200_mh_1754970445122718.png) 3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo

3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo![[list:title ] Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis](/runtime/image/mw200_mh_1754970599124240.png) Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis

Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis![[list:title ] Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M](/runtime/image/mw200_mh_1754970685778571.jpg) Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M

Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M![[list:title ] RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible](/runtime/image/mw200_mh_1754970772864871.jpg) RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible

RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible![[list:title ] Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P](/runtime/image/mw200_mh_1754970914446714.jpg) Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P

Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P![[list:title ] Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon](/runtime/image/mw200_mh_1754971132172086.jpg) Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon

Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon![[list:title ] 1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi](/runtime/image/mw200_mh_1754971206813424.jpg) 1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi

1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi![[list:title ] USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers](/runtime/image/mw200_mh_1751290248528158.png) USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers

USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers![[list:title ] Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine](/runtime/image/mw200_mh_1751290043732325.png) Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine

Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine![[list:title ] Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl](/runtime/image/mw200_mh_1751289911932558.png) Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl

Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl![[list:title ] OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir](/runtime/image/mw200_mh_1751289859503493.png) OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir

OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir![[list:title ] Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic](/runtime/image/mw200_mh_1751289819362910.png) Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic

Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic![[list:title ] Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C](/runtime/image/mw200_mh_1751289746509799.png) Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C

Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C![[list:title ] High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery](/runtime/image/mw200_mh_1751289703107392.png) High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery

High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery![[list:title ] High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC](/runtime/image/mw200_mh_1751289653205137.png) High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC

High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC![[list:title ] XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec](/runtime/image/mw200_mh_1751293406317163.png) XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec

XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec![[list:title ] XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3](/runtime/image/mw200_mh_1751293362444100.png) XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3

XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3![[list:title ] XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni](/runtime/image/mw200_mh_1751293307595602.png) XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni

XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni![[list:title ] Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou](/runtime/image/mw200_mh_1751293254961173.png) Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou

Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou![[list:title ] UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2](/runtime/image/mw200_mh_1751293224859016.png) UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2

UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2![[list:title ] PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St](/runtime/image/mw200_mh_1751293191631742.png) PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St

PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St![[list:title ] PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use](/runtime/image/mw200_mh_1751293135247963.png) PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use

PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use![[list:title ] OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co](/runtime/image/mw200_mh_1751293103170614.png) OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co

OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co![[list:title ] Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H](/runtime/image/mw200_mh_1751287652901338.png) Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H

Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H![[list:title ] Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation](/runtime/image/mw200_mh_1751287559833642.png) Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation

Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation![[list:title ] New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An](/runtime/image/mw200_mh_1751287256545420.png) New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An

New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An![[list:title ] M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw](/runtime/image/mw200_mh_1751287205474322.png) M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw

M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw![[list:title ] M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG](/runtime/image/mw200_mh_1751287108943181.png) M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG

M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG![[list:title ] JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes](/runtime/image/mw200_mh_1751287072360672.png) JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes

JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes![[list:title ] HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors](/runtime/image/mw200_mh_1751287006387917.png) HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors

HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors![[list:title ] High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe](/runtime/image/mw200_mh_1751286944271896.png) High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe

High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe