Wire harness assemblies are an integral part of modern electrical systems and are crucial to their functionality and efficiency. Along with organizing the intricate wiring, these assemblies ensure protection against damage and offer high durability and safety to the electrical systems. In addition, due to their organized nature, troubleshooting and maintenance have become faster and more cost-effective. These products are also critical in applications with limited space, such as industrial machinery, airplanes, or automobiles.

This guide will explore the step-by-step process of creating a reliable wire harness assembly.

What are Wire Harness Assemblies?

Wire harness assemblies are a group of electrical cables organized and enclosed within insulated sleeving and jacketing. They are designed to streamline and protect the wiring within various electrical systems. They comprise multiple cables, connectors, and wires terminated in specific configurations to accommodate complex applications.

Some wire harness assemblies are simple, while others are very complex, with intricate designs and configurations requiring detailed instruction and preparation. Such detailing ensures proper functionality and safety of the systems.

Which Industries Need Wire Harness Assemblies?

Some key industries that benefit from the advanced wire harness assemblies include:

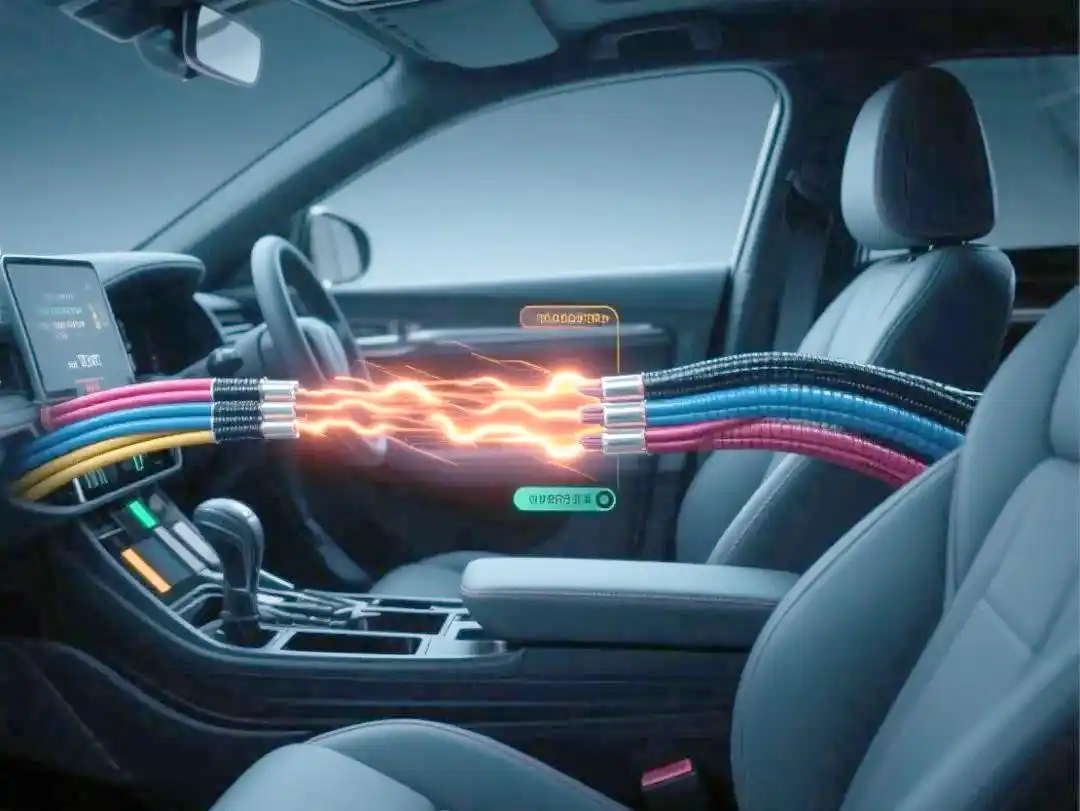

Automotive industry:

In modern vehicles, the functionality of different electrical systems depends on the functioning of the wire harness assemblies. These assemblies ensure the right electricity distribution and signals throughout your car. The assemblies ensure smooth and reliable operation by powering systems like ignition, infotainment, air conditioning, lighting, and power windows.

Aerospace:

These harnesses can withstand vibrations, moisture, and extreme temperature conditions, ensuring critical systems’ safe and efficient operation in military and commercial aircraft.

Manufacturing and industrial control:

Wire harness assemblies manage complex wiring systems of industrial and manufacturing environments, driving automation and controlling machinery. These assemblies keep the connections safe and organized, facilitating smoother assembly lines and improving the overall efficiency of the machines.

IT and communications:

Wire harnesses support modern data centers, routers, satellite receivers, and other systems in IT infrastructure. These complex and advanced wire assemblies ensure that communication hubs, broadband networks, and internet connections function seamlessly.

Medical industry:

Whether it’s diagnostic equipment, surgical tools, or patient monitoring systems, wire harness assemblies are everywhere in the healthcare sector. With the durability and capability of complex wiring, all life-saving medical equipment offers consistent performance in hospitals and clinics.

![[list:title ] Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for](/runtime/image/mw200_mh_1754970367606571.png) Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for

Factory Direct 6A Fast Charging 2-in-1 Type-C Data Cable TPE Jacket Super Fast Charging Function for![[list:title ] 3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo](/runtime/image/mw200_mh_1754970445122718.png) 3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo

3A/5A Fast Charging Intelligent Power-off Data Cable Type-C USB with Braided Jacket 1M Length for Mo![[list:title ] Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis](/runtime/image/mw200_mh_1754970599124240.png) Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis

Type-C Cable 1M Fast Charging Flexible Braided for Mobile Phone Power Bank with Gradient Shell Invis![[list:title ] Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M](/runtime/image/mw200_mh_1754970685778571.jpg) Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M

Factory Direct PD Type C-C Fast Charging Cable Pure Copper Braided Nylon Aluminum Alloy Jacket for M![[list:title ] RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible](/runtime/image/mw200_mh_1754970772864871.jpg) RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible

RGB Luminous Nylon Braided Fast Charging Side Lighting Seven-Color Type C Data Cable USB Compatible![[list:title ] Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P](/runtime/image/mw200_mh_1754970914446714.jpg) Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P

Factory Braided Shield USB Fast Charging Cable Type-C Micro Connectors for Mobile Phones Computers P![[list:title ] Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon](/runtime/image/mw200_mh_1754971132172086.jpg) Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon

Customized 1M 3A Fast Charging 4-in-1 Flat Metal Case USB Android Power Bank Type-C Connector Nylon![[list:title ] 1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi](/runtime/image/mw200_mh_1754971206813424.jpg) 1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi

1m Aluminum Alloy Transparent Connector Type-C Data Fast Charging Cable 2-in-1 Nylon Jacket with Foi![[list:title ] USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers](/runtime/image/mw200_mh_1751290248528158.png) USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers

USB 2.0 5-Pin SH Type Male Cable 1m Fast Charging 3A for Mobile Phones Power Banks Cameras Computers![[list:title ] Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine](/runtime/image/mw200_mh_1751290043732325.png) Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine

Universal PVC Insulated Copper Conductor Harness Wire Electronic Play Cable Plug for Gaming Machine![[list:title ] Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl](/runtime/image/mw200_mh_1751289911932558.png) Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl

Premium Custom PVC Insulated Auto Electrical Wiring Harness for Cars & Motorcycles Specific Appl![[list:title ] OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir](/runtime/image/mw200_mh_1751289859503493.png) OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir

OEM ODM Custom Motorcycle & Automobile PVC Insulated Electrical Wiring Harness Copper Custom Wir![[list:title ] Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic](/runtime/image/mw200_mh_1751289819362910.png) Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic

Manufacturer Customized PVC Insulated Copper Conductor Electrical Wire Harness for Electronic Applic![[list:title ] Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C](/runtime/image/mw200_mh_1751289746509799.png) Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C

Hot Sale 10PIN Female Flat Touch Screen Ribbon Cable RS232 Serial D-Sub DB9 9PIN Port IDC Male PVC C![[list:title ] High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery](/runtime/image/mw200_mh_1751289703107392.png) High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery

High Quality ZX330-5G Excavator Safety Relay 1825530391 24V Starter Essential Construction Machinery![[list:title ] High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC](/runtime/image/mw200_mh_1751289653205137.png) High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC

High Quality New Condition AUTO PARTS Wiring Harness 4HG1 NPR Cable Hand Brake Truck Wholesales PVC![[list:title ] XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec](/runtime/image/mw200_mh_1751293406317163.png) XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec

XHB High-Temperature Resistant Wiring Harness Locking Terminal Cable 200mm Length 12504H00-5P Connec![[list:title ] XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3](/runtime/image/mw200_mh_1751293362444100.png) XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3

XH2.54 JST Silicone Battery Wires Cable Connector 20cm Black Electronic Application 220mm Cable OC3![[list:title ] XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni](/runtime/image/mw200_mh_1751293307595602.png) XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni

XH2.54 JST 20cm Black Silicon Gel Wires Connector 380mm DC Ribbon Cable Wiring Harness for Electroni![[list:title ] Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou](/runtime/image/mw200_mh_1751293254961173.png) Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou

Wire Harness UL2468#24 White Blue 4P Ribbon Cable, One End HA-4P With Buckle, Other End HA-4P Withou![[list:title ] UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2](/runtime/image/mw200_mh_1751293224859016.png) UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2

UL-Certified Industrial Automation Servo Motor Cable 500mm Length Brown Blue PVC_PE Wires HA-6P SM-2![[list:title ] PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St](/runtime/image/mw200_mh_1751293191631742.png) PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St

PVC Plasticlogic Flexible Household Appliance Wiring Harness Tinned Copper Conductor One End Semi-St![[list:title ] PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use](/runtime/image/mw200_mh_1751293135247963.png) PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use

PVC Insulated Copper Conductor Wiring Harness Connector for Electric Cars for Automobile Use![[list:title ] OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co](/runtime/image/mw200_mh_1751293103170614.png) OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co

OEM UL2468 UL2651 Customized 5pin White Wiring Harness 1.27mm 2.0mm 2.54mm Electrical Wire JST XH Co![[list:title ] Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H](/runtime/image/mw200_mh_1751287652901338.png) Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H

Premium IP68 Waterproof Circular Connectors SP13 SP21 LED Cable Connector 2-7p Number Cores Wiring H![[list:title ] Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation](/runtime/image/mw200_mh_1751287559833642.png) Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation

Pole EV Battery Connector 8mm Copper Contact Material with 50A Rated Current Straight Orientation![[list:title ] New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An](/runtime/image/mw200_mh_1751287256545420.png) New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An

New Energy Inverter Battery Connectors 3P 120A Rated Copper Contacts EV Conversions with Straight An![[list:title ] M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw](/runtime/image/mw200_mh_1751287205474322.png) M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw

M12 Black Round Socket 2.5m Cable Waterproof 8-Pin Connector Enhanced IP67_IP68 Overmolded TPU Screw![[list:title ] M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG](/runtime/image/mw200_mh_1751287108943181.png) M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG

M12 3-Pin Connector Cable 1000mm Fast Electric Car Charging Station Single Output Indoor_Outdoor 8KG![[list:title ] JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes](/runtime/image/mw200_mh_1751287072360672.png) JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes

JL15EDGKNHM-35008B01 Black 2_8P Pitch 3.5mm 2 Row 8 Pin Terminal Blocks Position 2 for Wiring Harnes![[list:title ] HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors](/runtime/image/mw200_mh_1751287006387917.png) HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors

HVIL 2-Pin New Energy Vehicle Connector Socket 125A Capacity 25mm2 Cable Product Category Connectors![[list:title ] High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe](/runtime/image/mw200_mh_1751286944271896.png) High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe

High-Pressure PVC Insulated Wiring Harness for Automobiles Flexible Grease and Oil Hose H20PDU Coppe